Causes, solutions and preventive measures for air suspension airbags without air or wrinkles

Publish Time: 2024-11-01

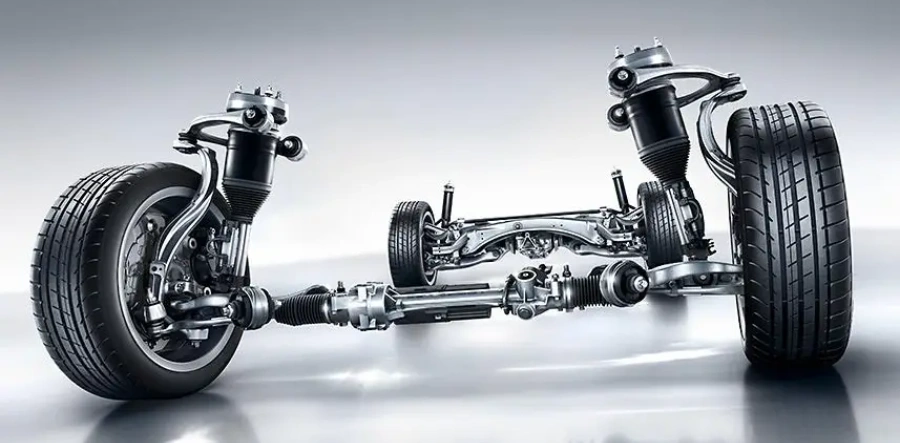

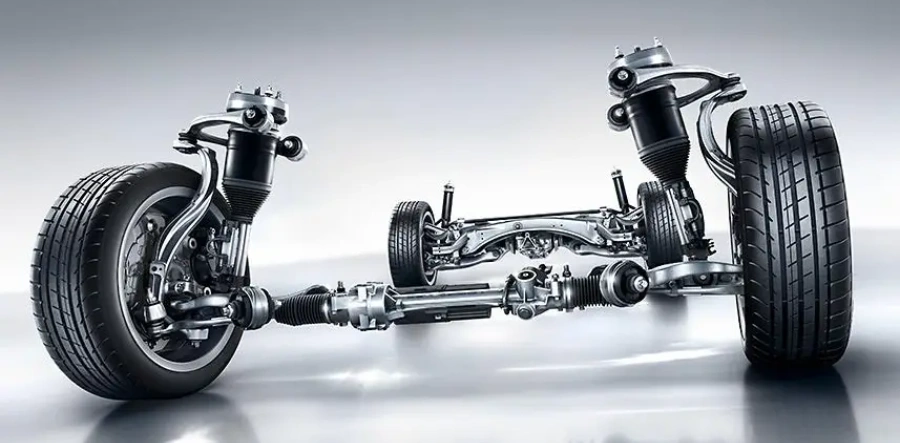

As an important suspension system of modern vehicles, the stability and reliability of air suspension performance are crucial to driving safety and ride comfort. However, in actual use, the problem of air suspension airbags without air or wrinkles often occurs, which not only affects the suspension performance of the vehicle, but also poses a potential threat to driving safety. 1. Cause analysisAirbags without air:Insufficient air pressure in the air reservoir: When the air pressure in the air reservoir is lower than a certain threshold (such as 0.6MPA), the pressure protection valve will suspend the air supply to the air suspension to ensure the normal operation of the braking system.Air pipeline problem: The air pipeline may be aging, worn, folded or blocked, resulting in poor gas circulation, which in turn affects the normal inflation of the airbag.Height control valve failure: As a key component of the air suspension system, the height control valve may cause uneven gas distribution if its connecting rod falls off or is damaged internally, and the airbag cannot obtain sufficient air pressure.Airbag wrinkles:Overstretching: When the vehicle is transported, hoisted, or in and out of the repair workshop, the airbag may be overstretched and not reset in time, resulting in wrinkles on the airbag surface.Impact of special road conditions: When the vehicle is driving on bumpy or steep roads, the frame may jump up excessively due to inertia, causing the airbag to be overstretched and wrinkled.Braking asynchrony: When the vehicle is parked or reversed, due to inertia, the rear of the vehicle will stretch upward, causing the height control valve to exhaust and the airbag pressure to be emptied. When the brake is released again, the whole vehicle will fall instantly, causing the airbag to wrinkle.2. SolutionNo air in the airbag:Check and adjust the air tank pressure: Make sure that the air tank pressure reaches the specified value. If it is lower than the set threshold, inflate it.Clean or replace the blocked air pipe: Perform a comprehensive inspection of the air pipeline, clean the blocked air pipe, and replace the damaged air pipe if necessary.Repair or replace the height control valve: Check the working status of the height control valve. If there is any problem, repair or replace it in time.Airbag wrinkles:Manually reset the airbag, disassemble the connection between the rubber connector under the vertical rod of the height control valve and the axle, lift the rod upward, let the airbag return to normal after it is fully inflated, and then install the rod back to its original position.If the airbag often has wrinkles during driving, you can consider adding a limiter between the axle and the frame to limit the excessive jump of the frame.For problems caused by asynchronous braking, the braking operation should be standardized. When parking or reversing, slowly stop the vehicle and then pull the handbrake.3. Preventive measuresRegular inspection and maintenance: Regularly conduct a comprehensive inspection of the air suspension system, including the air pressure of the air tank, air pipeline, height control valve and airbag status. If problems are found, repair or replace them in time to ensure that the system is in good condition.Standardize vehicle operation: Avoid over-stretching the airbag during vehicle transportation and hoisting or entering and leaving the maintenance workshop. When driving under special road conditions, slow down and avoid excessive jumping of the frame. When parking or reversing, standardize the braking operation to avoid excessive pulling up of the rear of the vehicle due to inertia.Add protective measures: Add a limiter between the axle and the frame to limit excessive jumping of the frame. Add a protective layer or protective device around the airbag to prevent hard foreign objects such as gravel from being drawn between the airbag and the lower piston (base).Improve driver awareness: Regularly train drivers on the air suspension system to improve their understanding of the working principle and common problems of the system. Encourage drivers to report problems in time when they are found during use so that they can be handled and repaired in time.By deeply analyzing the reasons why the air suspension airbag is empty or wrinkled, and taking effective solutions and preventive measures, the risk of failure of the air suspension system can be significantly reduced to ensure driving safety and ride comfort.

1. Cause analysisAirbags without air:Insufficient air pressure in the air reservoir: When the air pressure in the air reservoir is lower than a certain threshold (such as 0.6MPA), the pressure protection valve will suspend the air supply to the air suspension to ensure the normal operation of the braking system.Air pipeline problem: The air pipeline may be aging, worn, folded or blocked, resulting in poor gas circulation, which in turn affects the normal inflation of the airbag.Height control valve failure: As a key component of the air suspension system, the height control valve may cause uneven gas distribution if its connecting rod falls off or is damaged internally, and the airbag cannot obtain sufficient air pressure.Airbag wrinkles:Overstretching: When the vehicle is transported, hoisted, or in and out of the repair workshop, the airbag may be overstretched and not reset in time, resulting in wrinkles on the airbag surface.Impact of special road conditions: When the vehicle is driving on bumpy or steep roads, the frame may jump up excessively due to inertia, causing the airbag to be overstretched and wrinkled.Braking asynchrony: When the vehicle is parked or reversed, due to inertia, the rear of the vehicle will stretch upward, causing the height control valve to exhaust and the airbag pressure to be emptied. When the brake is released again, the whole vehicle will fall instantly, causing the airbag to wrinkle.2. SolutionNo air in the airbag:Check and adjust the air tank pressure: Make sure that the air tank pressure reaches the specified value. If it is lower than the set threshold, inflate it.Clean or replace the blocked air pipe: Perform a comprehensive inspection of the air pipeline, clean the blocked air pipe, and replace the damaged air pipe if necessary.Repair or replace the height control valve: Check the working status of the height control valve. If there is any problem, repair or replace it in time.Airbag wrinkles:Manually reset the airbag, disassemble the connection between the rubber connector under the vertical rod of the height control valve and the axle, lift the rod upward, let the airbag return to normal after it is fully inflated, and then install the rod back to its original position.If the airbag often has wrinkles during driving, you can consider adding a limiter between the axle and the frame to limit the excessive jump of the frame.For problems caused by asynchronous braking, the braking operation should be standardized. When parking or reversing, slowly stop the vehicle and then pull the handbrake.3. Preventive measuresRegular inspection and maintenance: Regularly conduct a comprehensive inspection of the air suspension system, including the air pressure of the air tank, air pipeline, height control valve and airbag status. If problems are found, repair or replace them in time to ensure that the system is in good condition.Standardize vehicle operation: Avoid over-stretching the airbag during vehicle transportation and hoisting or entering and leaving the maintenance workshop. When driving under special road conditions, slow down and avoid excessive jumping of the frame. When parking or reversing, standardize the braking operation to avoid excessive pulling up of the rear of the vehicle due to inertia.Add protective measures: Add a limiter between the axle and the frame to limit excessive jumping of the frame. Add a protective layer or protective device around the airbag to prevent hard foreign objects such as gravel from being drawn between the airbag and the lower piston (base).Improve driver awareness: Regularly train drivers on the air suspension system to improve their understanding of the working principle and common problems of the system. Encourage drivers to report problems in time when they are found during use so that they can be handled and repaired in time.By deeply analyzing the reasons why the air suspension airbag is empty or wrinkled, and taking effective solutions and preventive measures, the risk of failure of the air suspension system can be significantly reduced to ensure driving safety and ride comfort.About TND

TND Axle is a national high-tech group company specializing in the research and development, design and manufacturing of heavy-duty vehicle parts such as trailers and semi-trailers. It has obtained multiple international quality standard certifications such as IATF 16949:2016. The main products are: American axles, German axles, air suspension, bogie suspension, mechanical suspension and other trailer parts, with an annual output of about 100,000 sets of axle series and 20,000 sets of suspension series. TND has innovated and improved on the basis of military technology, creating a new era of seamless steel tube hot extrusion one-piece thickened axles. This advanced technology can greatly improve the strength, stiffness and fatigue life of the axle beam and reduce the risk of fatigue fracture of the axle. We have our own patented hot forming machines and other advanced equipment, including: fatigue testing machine, ultrasonic flaw detector, Brinell hardness tester, thickness gauge, spectrometer, metallographic analyzer, coordinate measuring machine, etc., and are supported by professional engineers in our R&D department and a strict quality control team.TND Axle's industry experience has won the trust and welcome of the majority of users. We will continue to provide high-quality trailers, semi-trailers and other heavy-duty vehicle parts and good after-sales service to new and old customers for common development! TND looks forward to working with you to create a brilliant and win-win future.